Payment Type:T/T

Incoterm:FOB,CIF,EXW

Transportation:Ocean,Air

Port:Shanghai,Zhenjiang,Nanjing

Brand: Rayhot

Any Size Can Be Customized: any size can be customized

Packaging: Carton Packing and wooden box package

Transportation: Ocean,Air

Place of Origin: China

Port: Shanghai,Zhenjiang,Nanjing

Payment Type: T/T

Incoterm: FOB,CIF,EXW

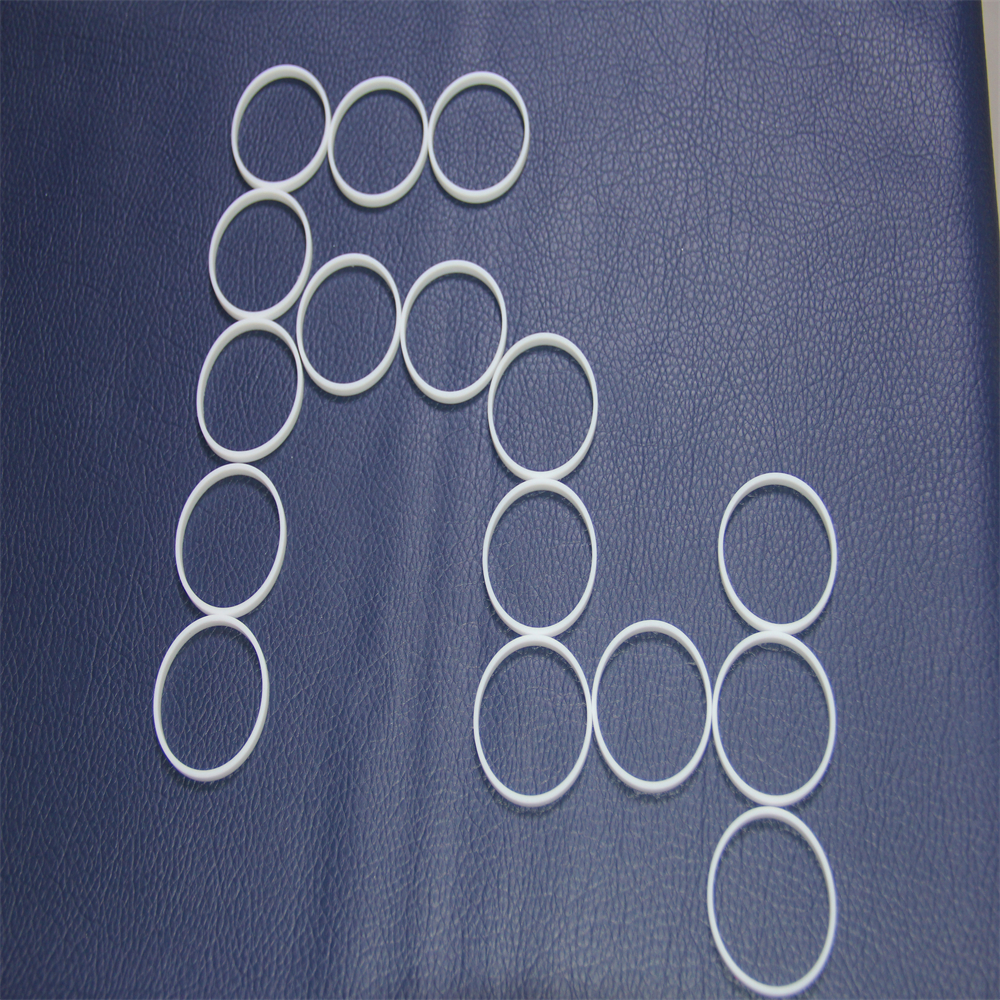

Ceramic PTFE filled spiral wound gaskets:

Product Description:

Ceramic PTFE filled spiral wound gaskets are a type of sealing gasket that is made from a combination of ceramic and PTFE materials. The ceramic provides excellent thermal and chemical resistance, while the PTFE enhances its sealing properties.

Unfilled Ptfe Round Bar Moulded Rod

Low temperature resistance Ptfe Tube

Customized size 16mm Ptfe Rod

Production Process:

The production process involves winding a metal strip with a ceramic PTFE filler around a metal core. The wound strip is then compressed to create a tight seal.

Manufacturing Technology:

The manufacturing technology used is state-of-the-art, with strict quality control measures in place to ensure the highest level of product quality.

Raw Material Advantages:

The use of ceramic and PTFE materials provides excellent chemical and thermal resistance, making it ideal for use in harsh environments.

Product Performance and Advantages:

Ceramic PTFE filled spiral wound gaskets offer exceptional sealing performance, with high temperature and pressure resistance. They are also resistant to corrosion and are highly durable, making them ideal for long-term use.

Installation Steps:

The gasket should be placed between the flanges and tightened to the recommended torque value.

Customed your PTFE Parts ptfe discs

Filling machine use machined Ptfe Bellows

Lifespan:

The lifespan of the gasket depends on the specific application and operating conditions. However, with proper installation and maintenance, they can last for many years.

Rayhot Hydrophobic PTFE Membrane

Rayhot Hydrophilic Soluble Ptfe Membrane

Precautions:

It is important to ensure that the gasket is properly installed and tightened to prevent leaks. It is also important to use the gasket in the appropriate temperature and pressure range.

Service Guarantee:

We offer a comprehensive service guarantee, including technical support and after-sales service.

Packaging:

The gaskets are packaged in a protective material to prevent damage during transport and storage.